Disrupting Commercial Solar: Why Installers Are Switching to the QT2

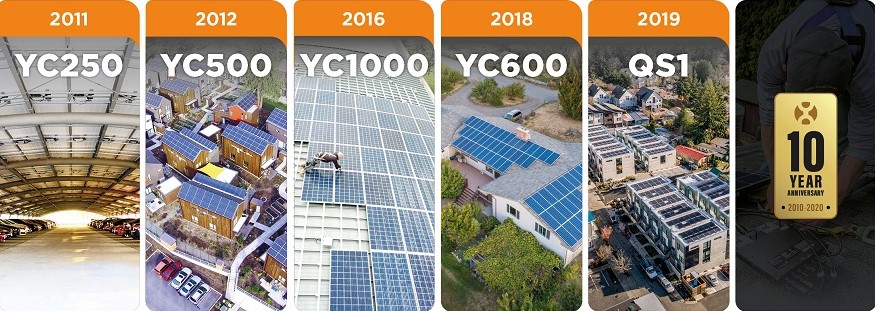

In the rapidly evolving solar industry, performance, ease of installation, and long-term reliability are critical factors. APsystems’ QT2 microinverter has emerged as a game-changer in commercial solar installations, offering unparalleled efficiency, safety, and scalability. Backed by third-party validation and innovative engineering, the QT2 is reshaping expectations for commercial solar technology.

Third-Party Validation: Confidence Built on Proof

The QT2 microinverter has undergone rigorous independent testing by the Renewable Energy Test Center (RETC), which confirmed its exceptional 4-in-1 design and overall performance. Additionally, APsystems’ commitment to quality is underscored by a third-party bankability report from DNV on the DS3 product line. This provides further evidence of the platform’s reliability, demonstrating that the QT2 is built on a solid technological foundation.

Performance-Driven Innovation

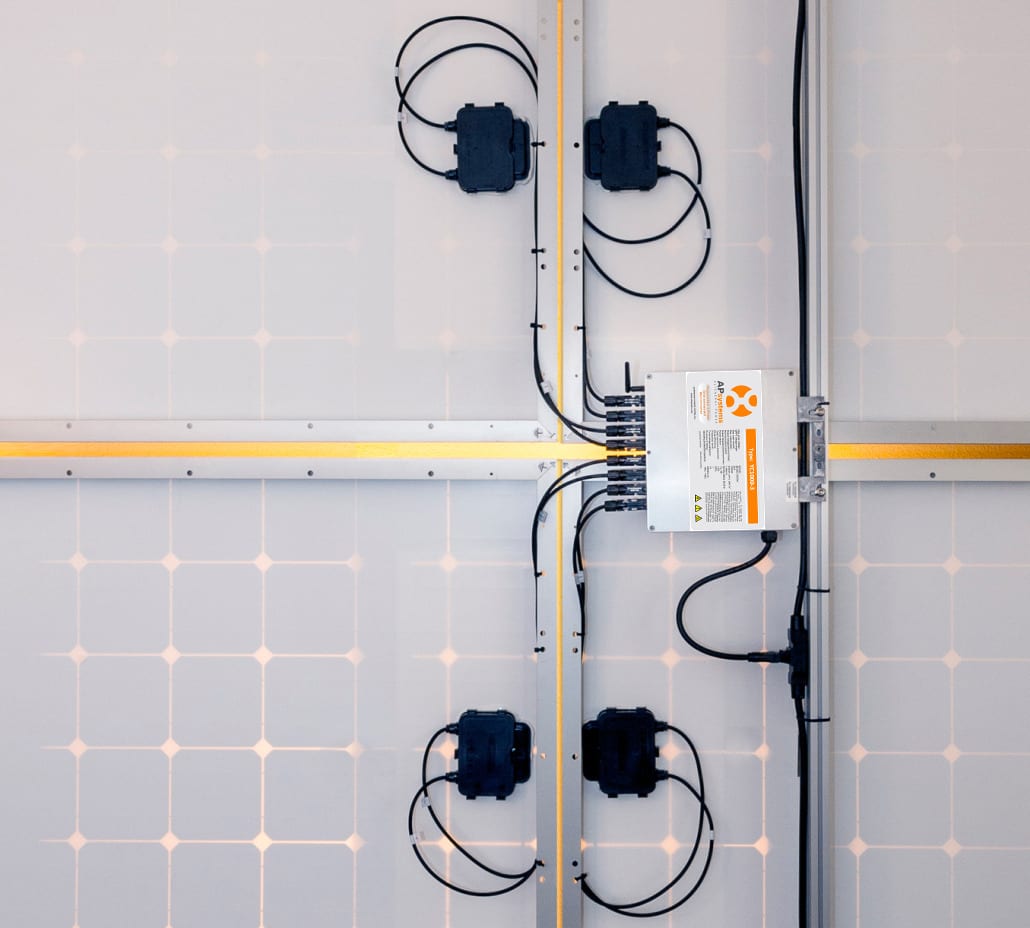

The QT2 is not just another microinverter; it’s specifically designed for commercial applications. Key features include:

- Variants: Available in both 208V and 480V models, addressing diverse project needs.

- High Power Output: Up to 1800W per unit, capable of supporting four high-capacity modules, including today’s 575W+ PV modules.

- Integrated Design: Built-in phase balancing and monitoring for native compatibility with 3-phase systems.

- Standards Compliance: Fully adheres to UL 1741 SB, including rapid shutdown requirements with appropriate equipment.

This innovative approach reduces the number of inverters required for installations, cutting installation time and minimizing potential failure points by up to 75% compared to traditional setups.

Enhanced Features and Rigorous Testing

APsystems continues to push the envelope with the QT2 by integrating enhanced features and maintaining rigorous quality standards:

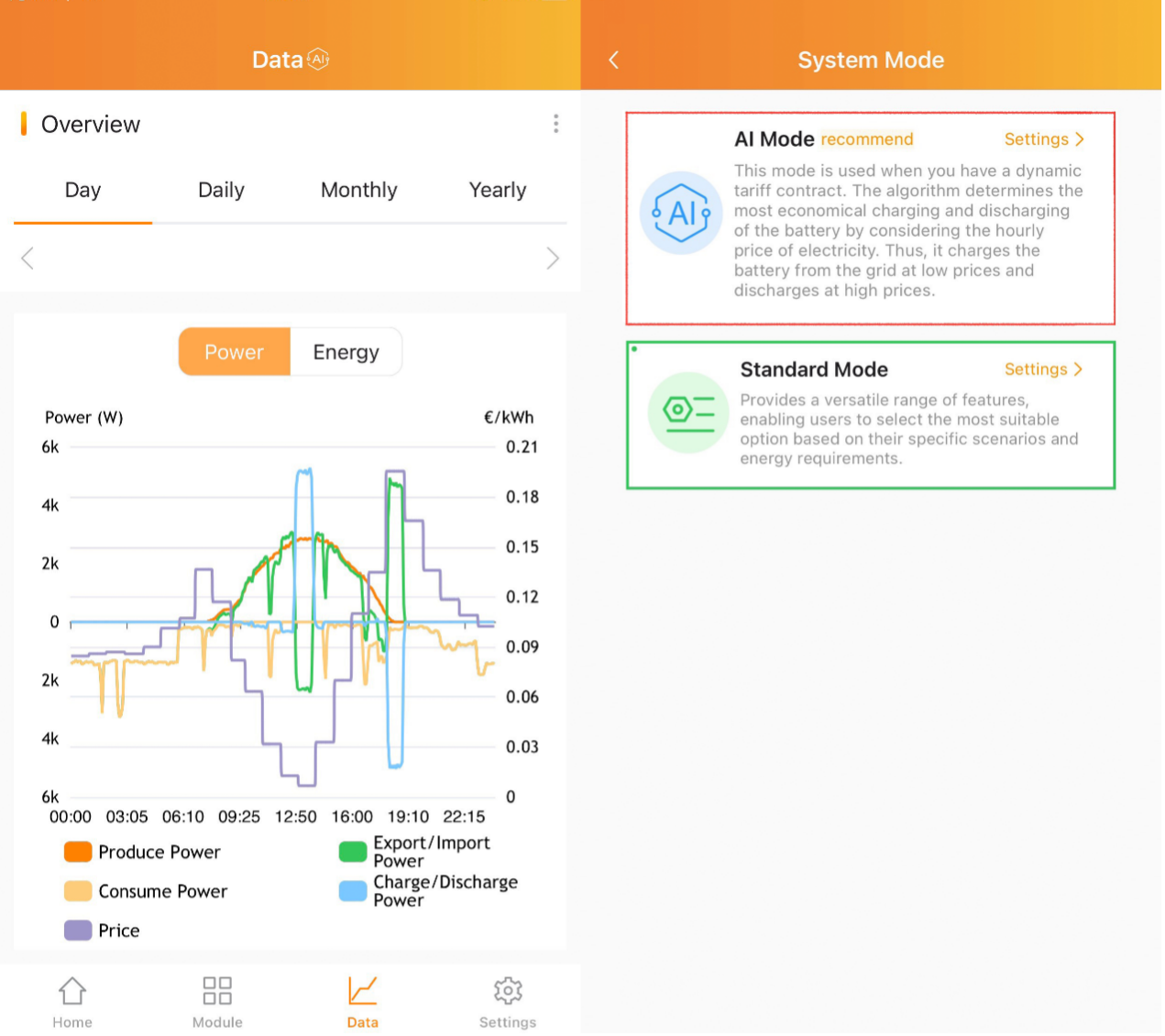

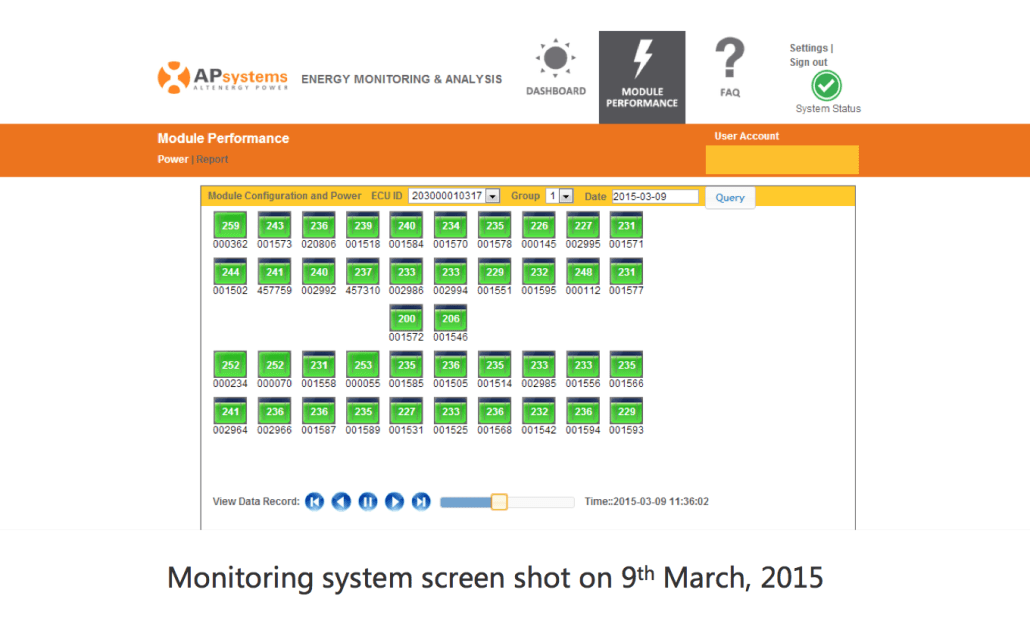

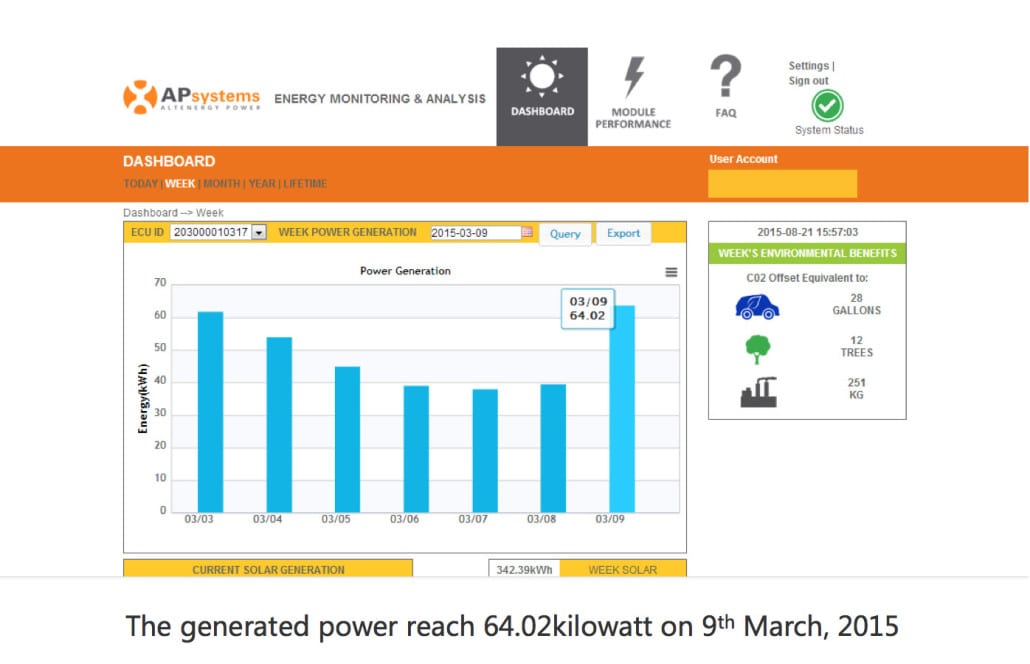

- Upgraded software for better system visibility and real-time analytics through the Energy Monitoring & Analysis (EMA) portal.

- Refined supply chain logistics, ensuring broader availability and easier deployment of the QT2.

- Comprehensive in-house testing to meet and exceed industry expectations for reliability and performance.

Why Commercial Installers Are Choosing the QT2

The QT2 microinverter offers competitive advantages that resonate with commercial solar professionals:

- Unmatched Efficiency: A 4-in-1 design leads to faster installations and reduced labor costs.

- High Compatibility: Works seamlessly with bifacial, split-cell, and large-format modules up to 600W+.

- Built for Scale: Plug-and-play architecture enables easy expansion and flexible array design.

- Smart & Secure: Features Zigbee wireless mesh networking and module-level monitoring, including 3-phase consumption tracking via ECU-C.

- Proven Reliability: Built on a trusted platform validated by third-party testing and millions of microinverters deployed globally.

Conclusion: It’s Time to Go QT2

As the demand for commercial solar continues to rise, selecting the right technology partner is more important than ever. APsystems’ QT2 microinverter delivers proven reliability, enhanced energy performance, and peace of mind—all supported by third-party validation and continuous innovation.

With its advanced features, streamlined installation process, and scalable design, the QT2 is setting a new standard for commercial solar projects. Now is the perfect time to integrate the QT2 into your solar installations and experience the difference firsthand.

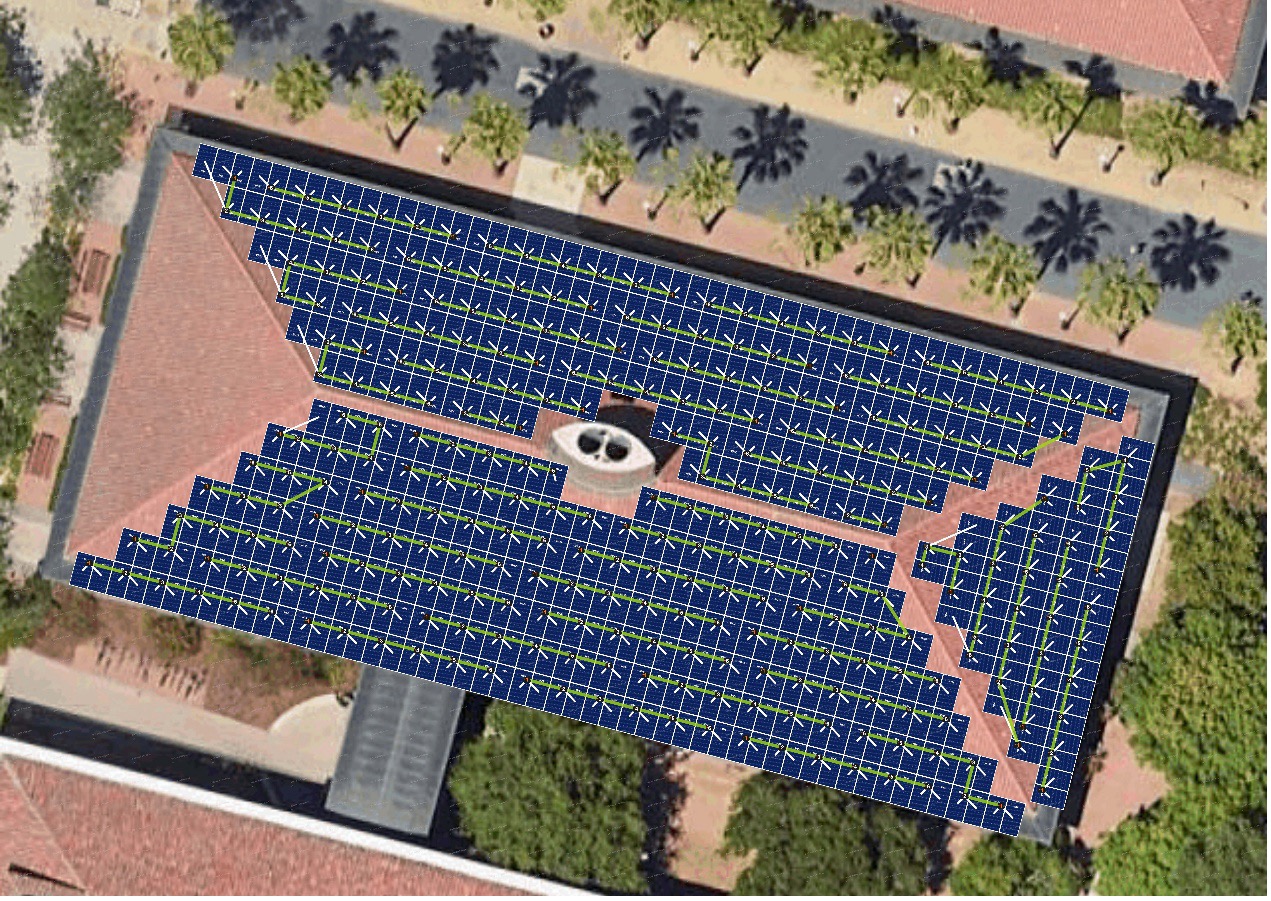

Mr. Li was surprised by the system’s output.

Mr. Li was surprised by the system’s output. Mr. Li is glad he chose APsystems microinverters for the installation, to optimize system output through module-level harvest and monitoring, and a lower startup voltage than offered by conventional “string” inverters.

Mr. Li is glad he chose APsystems microinverters for the installation, to optimize system output through module-level harvest and monitoring, and a lower startup voltage than offered by conventional “string” inverters. Renewable energy will be increasingly popular in the future, with the support of the Chinese government and public. APsytems advanced microinverter technology will be there to help new solar investors get the most out of their home PV systems.

Renewable energy will be increasingly popular in the future, with the support of the Chinese government and public. APsytems advanced microinverter technology will be there to help new solar investors get the most out of their home PV systems.